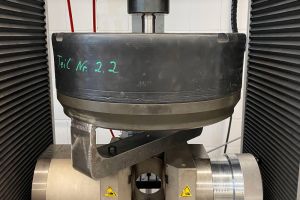

Protector Tests

Exquip Protectors are continuously tested according to IADC/SPE 17209, 11396 and API 5CT Annex F to match and exceed these specifications. Every year, a selection of different tests is carried out and documented - partly "in-house" but also in an independent test laboratory - to ensure a consistently high material and product quality, which is essential for our customers and their end customers in order to avoid failures or production downtimes on their side.

High strength elasticity and natural stability achieved through utilization of advanced polymer engineering and self-developed manufacturing methods eliminates the need for steel reinforcements which is used as dimension stabilizing element in composite protectors.

On-site experience shows the positive relaxation characteristics oft he material that prevents EXQUIP protectors from jamming even under the heaviest impact in the field.

Below are three test categories that are being expanded continuously with new tests and results.